Dorit S. Hochbaum and Sheng Liu

Accurate yield prediction in integrated circuit manufacturing enables accurate estimation of production cost and early detection of processing problems. It is known that defects tend to be clustered and a chip is likely to be defective if its neighbors are defective. This Neighborhood Effect is not well captured in traditional yield modeling approaches. We propose a new yield prediction model, called adjacency-clustering which addresses, for the first time, the neighborhood effect, and delivers prediction results that are significantly better than state-of-the art methods.

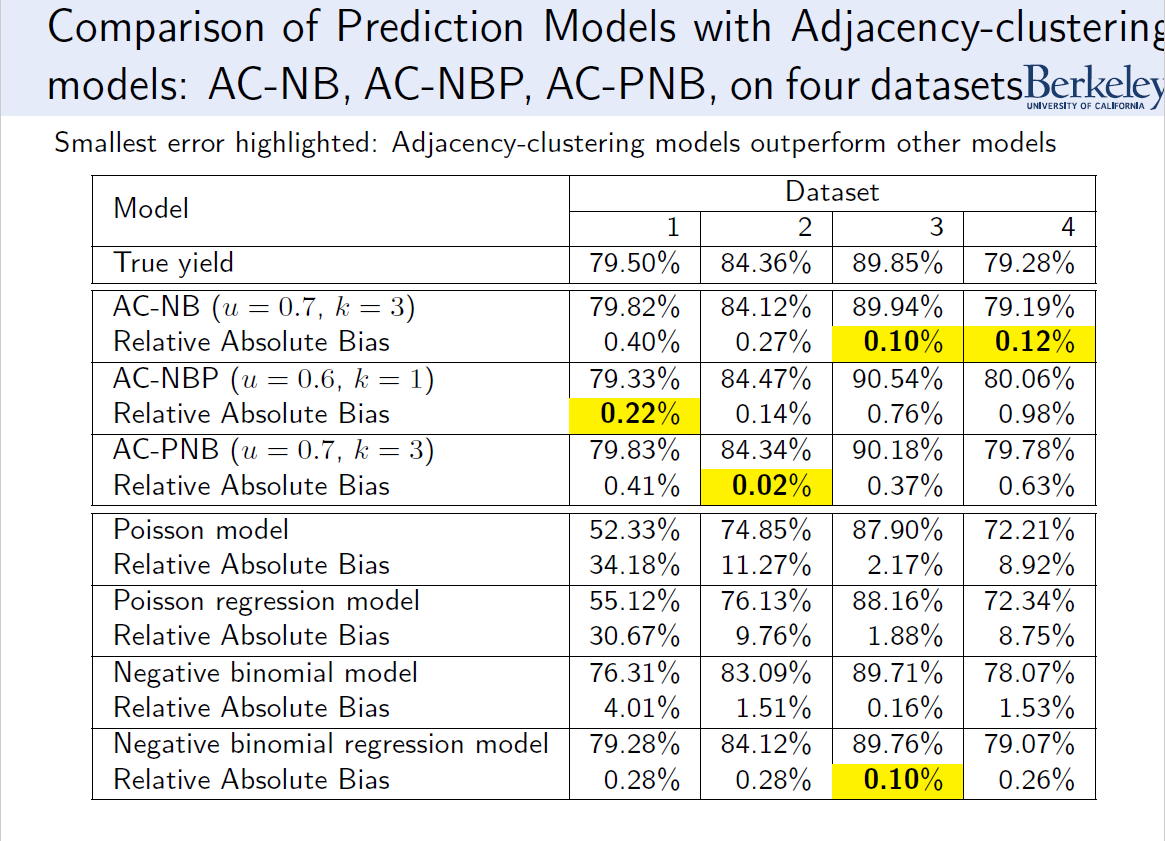

Adjacency-clustering (AC) model is a form of the Markov random field minimum energy model (MRF) that is primarily known in the context of image segmentation. AC model is a novel use of MRF for identifying defect patterns that enable diagnosis of failure causes in the manufacturing process. The defect patterns obtained by the AC model are then utilized for yield prediction. We compare the performance of the AC model to that of leading yield prediction models including the Poisson, the negative binomial, the Poisson regression and negative binomial regression models, on real datasets and on simulated datasets. The results demonstrate that the adjacency-clustering model captures the neighborhood effect and delivers superior prediction accuracy. Moreover, the concept and methodology of adjacency-clustering are not limited to integrated circuit manufacturing. Rather, it is applicable in any context where a neighborhood effect is present, such as disease risk mapping and energy consumption prediction.